ASSOC. COMPANY

8 Aug 2014

10 most common water storage tank remedials to achieve L8 compliance

Cold water storage tanks pose one of the highest risks of Legionella growth within a building’s water system, due to the possibility of stagnation, temperature gain and contamination.

Regular inspections of the tank and microbiological sampling are important features of a water hygiene control scheme required by ACoP L8, but these actions will prove inadequate if the tank design is not up to standard. To help you understand some of the current guidance notes such as BS8558, ACoP L8, HSG274 and the Water Regulations, W.E.T’s Legionella technicians have put together the top 10 most common tank repairs, which we regularly undertake to help building owners and facility managers achieve compliance, along with the relevant legislation and our recommendations from section 3.2 of our Legionella risk assessments.

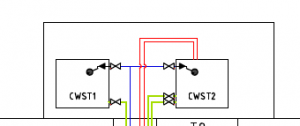

1 - Cold water storage tank (CWST) has the inlet and outlets on the same side

|

|

Problem |

Solution |

2 - The cold water storage tank has a damaged lid

|

|

Problem |

Solution |

3 - Access to the cold water storage tank is difficult and intrusive for monitoring

|

|

Problem |

Solution |

4 - Cold water storage tank has a light sediment build up and debris on the base

|

|

Problem |

Solution |

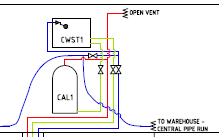

5 - Cold water storage tank has an open vent from the calorifier

|

This drawing shows a preferential scenario, whereby both calorifiers fitted with open vents discharge to a separate location |

Problem |

Solution |

6 - Cold water storage tank does not have a suitably screened airvent

|

|

Problem |

Solution |

7 - The cold water storage tank has a loose lid

|

|

Problem |

Solution |

8 - The cold water storage tank has structures creating a crevice for debris build up

|

|

Problem |

Solution |

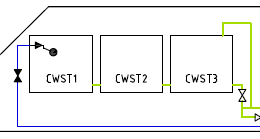

9 - The cold water storage tanks are configured incorrectly allowing inadequate circulation

|

|

Problem |

Solution |

10 - The warning pipe on the cold water storage tank does not discharge to a conspicuous location

|

|

Problem |

Solution |

If any of these are present within your water system, please contact the knowledgeable team at W.E.T for advice on 01827 288810.